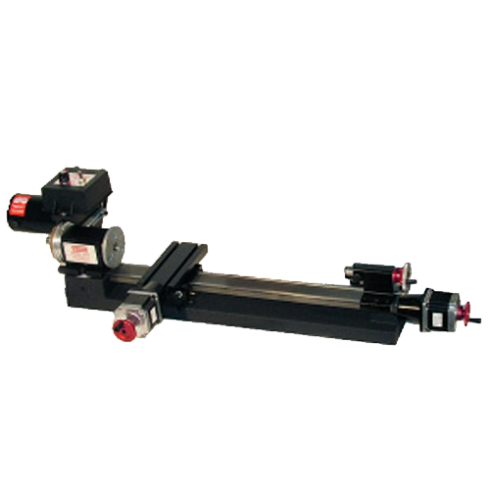

CNC Lathe System (VPL-CNC-4410)

The model 4410 has 90 VDC motor with electronic speed controller, a 2.75″ (70mm) x 6.0″ (152mm) crosslide, pulleys, belt, faceplate, lathe dog, two dead centers, three hexagonal keys, sharpened high-speed steel cutting tool, eight-foot and three-wire power cord. In addition, it has a 24″ (610mm) bed that has 17″ (430mm) between centers, a 2.5″ (63mm) resettable “zero” handwheel on the leadscrew, two 2″ (51mm) resettable “zero” handwheels on the crosslide and feed screw and a rocker tool post substituted for the standard tool post used on the shortbed lathes. The electronic speed control allows continuously variable speed control from 70 to 2800 RPM without belt changes.

SPECIFICATIONS

Swing over bed: 3.50″ (90 mm)

Swing over carriage: 1.75″ (45 mm)

Distance between centers: 17.00″ (430 mm)

Hole through spindle: .405″ (10 mm)

Spindle nose thread: 3/4″-16 T.P.I .

Spindle nose taper: #1 Morse

Travel of crosslide: 4.25″ (110 mm)

Taper of tailstock spindle: #0 Morse.

Protractor graduations: 0° to 45° by 5°

Handwheel graduations: 0.01 mm

Length overall: 37.25″ (947 mm)

Width overall: 10.75″ (273 mm)

Height overall: 8″ (200 mm)

Shipping weight: 30 lb. (13.6 kg)

Motor: 90 Volt DC with electronic speed control, input: 220 VAC, 50 Hz or 60 Hz

Spindle speed range: 70-2800 RPM continuously variable by electronic speed control

CNC stepper motor holding torque: 136 oz-in

Rapid travel speed, X and Z: 22 inches/min

Note: Specifications can be changed, added or subtracted without notice in our constant efforts for improvement.