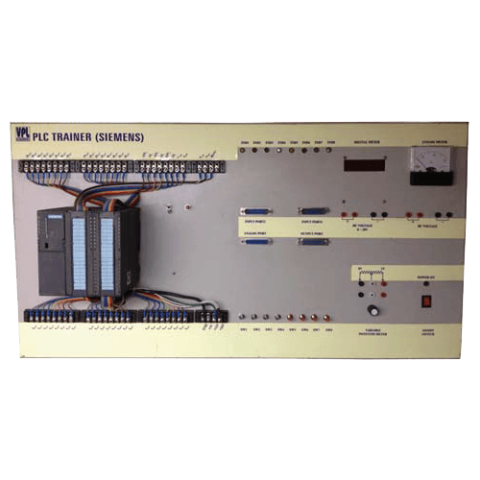

PLC Demonstration Trainer (VPL-PLCT)

DESCRIPTION

PLC Trainer has been designed in a different way than conventional PLC suitable to impart training and use of PLC in Process Industry for students at all levels with 16 Input Switches and 16 Output LEDs to simulate the Ladder Program, assembler to generate ladder programs, descriptive user manual with number of examples including description & fundamentals of PLC, number of Experimental Panels to be connected to the PLC for practical demonstration of PLC uses (optional)

- General Details

PLC Trainer has been designed in a different way than conventional PLC suitable to impart training and use of PLC in Process Industry for students at all levels with:

- 16 Input Switches and 16 Output LEDs to simulate the Ladder Program.

- Assembler to generate ladder programs.

- Descriptive user manual with number of examples including description & fundamentals of PLC.

- Number of Experimental Panels to be connected to the PLC for practical demonstration of PLC uses (optional).

Note: Specifications of any product can be changed or added without notice in our constant efforts for improvement.

- SPECIFICATIONS

- Microcontroller Based modular Mini PLC Trainer.

- PLC Trainer consisting of main unit, Hand held programming unit.

- Separate control for P,I,D channel gains.

- 16 input signals (24V) and 16 outputs for controlling the process on D-type sub connector.

- Programming unit: Hand held model with 28 keys and 6 digit display.

- Static process control simulator board consisting of switches and 16 LEDs for input simulation and 16 LEDs for output indications respectively.

- RAM module with battery backup to store the programmes.

- RS232C port available for uploading & downloading of files from PC.

- Powerful commands like AND, OR, ANI, ORI, SET, RST, LD, LDI, OUT, TIMER, COUNTER, ANB, ORB, IL, ILC, etc. directly executable.

- Model Programmes for the following process provided for the guidance of the User.

- SIMULATED EXPERIMENTAL MODULESFollowing static process simulator board/model setup are required to test the developed programmes:

- Seven segment display simulator for displaying a message.

- Washing Machine/Automatic Process.

- Burglar Alarm/Security Light.

- Traffic Light/Pedestrial Crossing.

- Door Security System.

- Warehouse Lift System/Lift Control.

- Star Delta Process.

- Resistance Welding System.

- *NoteNote: Specifications of any product can be changed or added without notice in our constant efforts for improvement.

- Related Products